Articles by Day: December 15, 2020

Prevent PCB Corrosion of Electronics With Anti-Tarnish Vapor Capsules

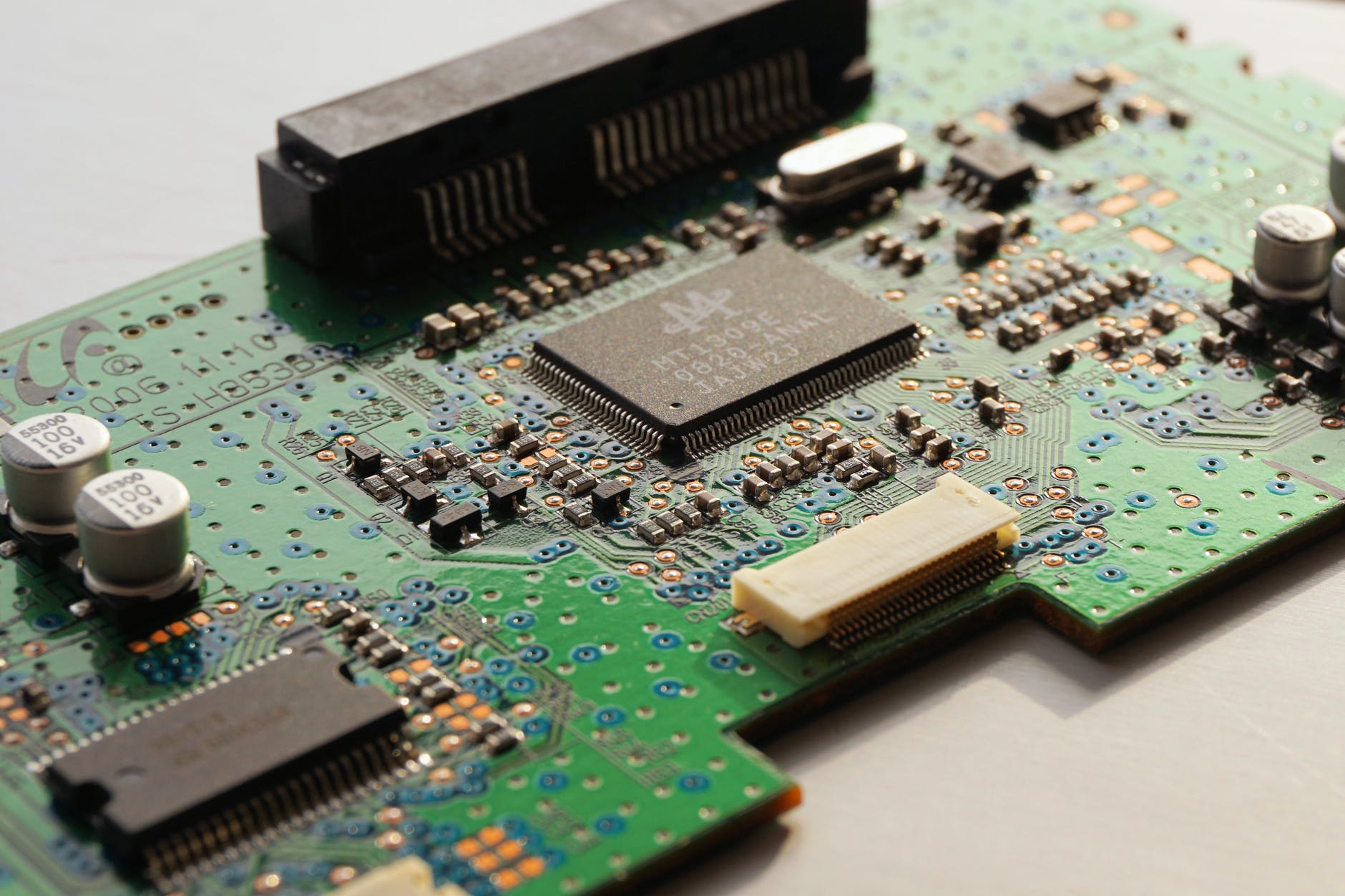

Printed circuit boards, widely known as PCBs, have a broad range of applications, including X-Ray screens, CT scanners, home appliances, entertainment systems, computer systems and smartphones. Because it’s used in so many systems, PCB corrosion of electronics is a major…