corrosion inhibiting

Gear Up For Spring With VCI Rust Prevention

Winter is almost over, and as we move into the warmer months, spring cleaning and planning for summer activities is always a high priority. It’s the ideal time to clean out the garage or basement, and to get bicycles, motorcycles,…

- Categorized: corrosion inhibiting, gun rust, Storage, VCI

Rust Prevention Spray Protects Metal Up to 1 Year Outdoors

Rust prevention spray can go a long way toward shielding metal-made equipment, tools, machinery, or furniture used outdoors for extended periods. Commercially marketed to manufacturers shipping items via ocean freight, the Zerust Axxanol Spray-G has also proven effective for protecting…

Tips to Prevent Boat Trailer Rust and Corrosion

If you own a boat, chances are you own a boat trailer to get your vessel to-and-from various waterways, as well as into and out of the water. Boat trailers, for the most part, are made up of one of…

Optimal Auto Parts Storage Solutions Include Rust & Corrosion Inhibitors

Car parts can deteriorate pretty quickly in storage if not properly prepared, packed, and protected from the elements. One of the most significant threats to any metal-made product is corrosion. This is as true for occasional weekend tinkerers as it…

5 ATV Storage & Maintenance Tips for Extending the Life of Your Quad

ATV mileage and hours can tell you a lot about its condition and performance – but proper ATV storage and maintenance is just as important. A poor quality ATV that is hard-used and ill-maintained isn’t likely to last beyond 200…

Prevent Corrosion and Rusted Electric Control Panels With VCI Plastabs

Corrosion and rusted electric control panels pose a major risk not only to the functionality of the features controlled by that panel, but also to the safety of those inhabiting that space at any given time. The presence of metal…

- Categorized: corrosion inhibiting, Rust Prevention Tips

- Tagged: control panel corrosion, corroded electrical panels, electric panel corrosion, electrical panel corrosion, prevent electric panel corrosion, prevent rust control panel, prevent rust electric panel, rusted control panels, rusted electric control panels, rusted electrical panels

The Best Motorcycle Covers Keep Your Bike Safe From Rust and Corrosion

May is motorcycle safety awareness month, and spring marks the start of prime riding season in many areas of the U.S. It’s a good time to note that keeping your bike road-worthy is key to ensuring safety on the streets.…

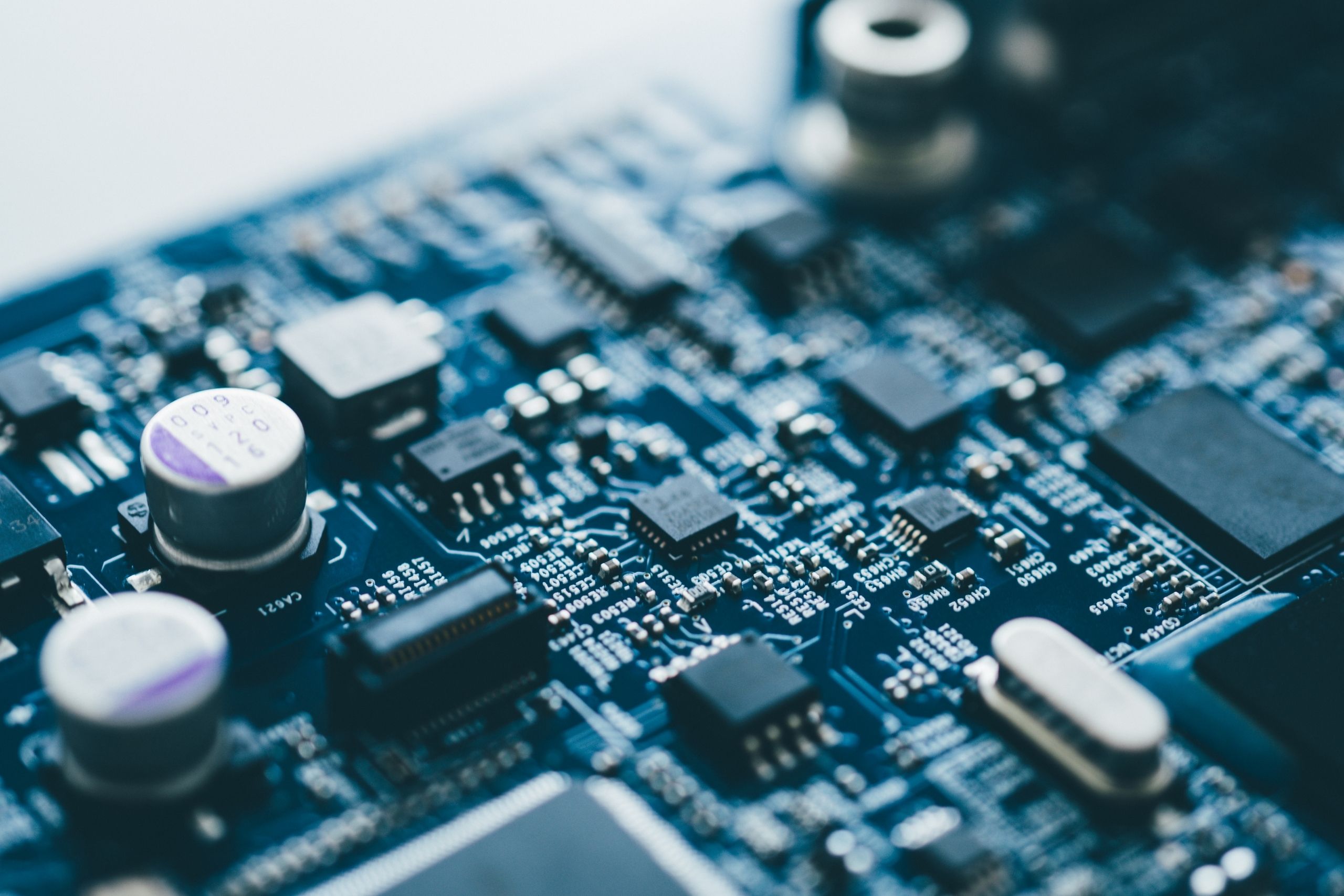

Prevent PCB Corrosion With Zerust Vapor Capsules, Plastabs, Drawer Liners

Electronics corrosion almost always involves some type of damage to printed circuit boards (or PCBs). These are the foundational building block of most modern electronics. One might consist of a single, layered board used in a remote garage door opener,…

Battling Aluminum Boat Corrosion Off Saltwater Shores

The last two years, there has been explosive demand for boats. The National Marine Manufacturers Association (NMMA) reports retail sales units of power boats, personal watercraft, wake boats, and freshwater fishing and pontoon boats have sailed well beyond a 20…

Rust-Busting Plastabs Prevent Corroded Tools

Hammer or hand saw, screwdriver or square – the tools in your toolbox have a broad range of uses, but all share a single foe: Rust. Prevention of corroded tools can be as simple as tossing in a tiny, thin…

Preventing Electronics Corrosion on Computers, Integrated Circuits, and Microchips

Electronics corrosion can occur in integrated circuits, microchips, lighting systems, PCB assemblies, marine equipment, and computers – all of which are broadly used and routinely exposed to potentially destructive environmental conditions. Corrosion can be costly and potentially dangerous for individuals,…

Rust Damage and Corrosion are Ongoing Battles for Governments, Consumers

Anyone who’s ever had the unfortunate surprise of discovering rust damage on a tool, bicycle or boat knows how quickly it can ruin your day and blow your budget. Turns out, the U.S. Department of Defense can empathize – on…

- Categorized: corrosion inhibiting, Rust Inhibitor, Rust Prevention Tips

- Tagged: rust damage

Prevent Brass Instrument Tarnish With Zerust Anti-Tarnish Capsules

There is something about brass that produces a great, rich timbre – perfect for musical instruments. Brass is a non-ferrous metal, meaning it contains no iron and therefore cannot rust. However, it is comprised of zinc and copper, which can…

Prevent Steel Corrosion of Valuable Metal Parts With VCI Poly Bags

Many manufacturers and shippers rely on steel components in production. Some store valuable metal parts on shelves for months or years on end, with the assurance it will be available at a moment’s notice if needed. The last thing any…

VCI Vehicle Covers Trusted to Keep Corrosion, Rust in Check on Snow, Ice Removal Trucks

The rumble of snow plows, salt trucks and other road-clearing commercial vehicles is increasingly common as we enter the thick of winter storm season. Most regions in the U.S. experience snow and ice storms to some degree each year, and…

- Categorized: corrosion inhibiting, Rust Prevention Tips, VCI

- Tagged: anti-rust car covers, VCI car covers, VCI corrosion protection, VCI covers, VCI vehicle covers

Don’t Let Boat Rust Keep You Anchored This Summer

Preventing boat rust isn’t solely about ensuring your ship shines. It’s about the assurance it stays seaworthy and protecting your investment. Beyond just being unsightly, boat rust and corrosion can spring a huge leak in your bank account because, as…

Zerust ATV Cover Keeps Quad Rust-Free

An estimated 10.5 million people in the U.S. live in homes wherein one or more resident owns an all-terrain vehicle (ATV). Through the mud, snow, ice or other rough turf, we put our ATVs through a world of punishment –…

- Categorized: corrosion inhibiting, Rust Prevention Tips

- Tagged: ATV Cover, ATV rust prevention cover, rust prevention

Rust on Electronics Costly in Increasingly Digital Age

Rust on electronics is an increasingly common problem in our modern world. Your PC, home entertainment gear, gaming equipment, electronics in your car or boat – all of it may be vulnerable to rust damage. Because rust on electronics and…

Air Conditioner Covers Protect Your HVAC System in Cooler Months

If you live in a cooler climate, chances are you aren’t giving much thought to your air conditioner right now. You should. Air conditioner covers can help prevent system failures that require expensive repairs and replacement. Protecting your HVAC unit…

Now Be Thankful

Zerust HQ – Workbench Despite the fact that rust never sleeps, it’s that time of year when we set our burden down, and take stock of all that we are thankful for. And so, on this day before Thanksgiving, we’d…

- Categorized: Announcements, corrosion inhibiting, Insights, Rust Prevention Tips

- Tagged: anti corrosion coating, corrosion inhibiting, rust prevention products